MINNEAPOLIS — Most consumers have probably noticed supply chain issues have caused grocery items to cost a little more or even be out of stock.

But now experts say the continued disruption due to COVID-19 may also be affecting the quality of what you buy.

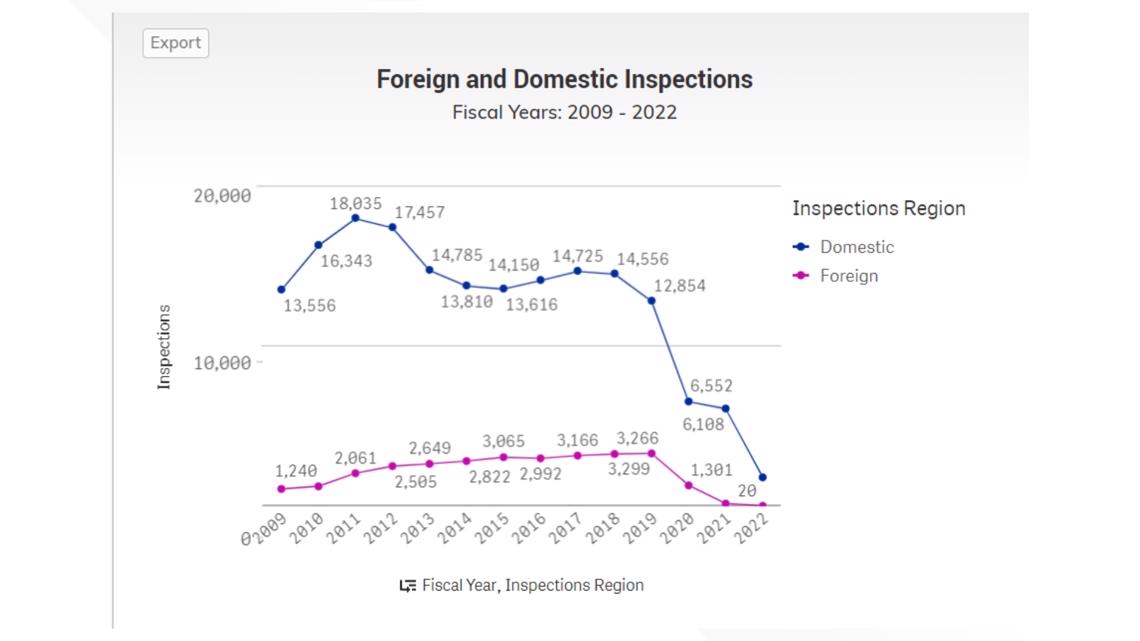

The past few years, the FDA has been conducting far fewer domestic inspections.

"They are definitely becoming more lenient in the way they are going through the process and letting products come to market," said Rachna Shah, professor of supply chain and operations with the Carlson School of Management at the University of Minnesota.

In 2018, the FDA conducted 14,556 domestic inspections. In 2019, the number was 12,854. Once COVID happened, the number dropped drastically. Only 6,552 inspections were conducted in 2020 and 6,108 in 2021.

Shah says there is no data on how many inspection waivers are being granted to certain products by U.S. Customs and Border Protection (CBP).

However, she says, "there is anecdotal evidence to suggest that CBP is giving more deferrals, CBP is giving more waivers, but we just don’t know how many."

Shah says the inspections are just one part of the concern; there are also a number of delays in the shipping process that keep stacking up.

"During COVID, transit time from China to Pacific coast is taking longer, I think on average, November data showed that it is taking six to eight days longer. So it is a greater likelihood that [a product] is going to get bad," she said.

On top of that, when the ships reach the port, there often isn't someone to unload and inspect them right away.

"There are no unloading workers, so now it takes a little longer, because now it has to wait until workers can unload the ship," she said. "The truckers are at shortage. The drivers are at shortage...which means all of these delays are likely to have quality issues as the product goes through. My worry – first level risk is, are we finding the problems when the products are getting inspected at the port?"

Shah says time will soon tell what the long-term impacts will be to both the consumer and the manufacturer. In the meantime, she urges consumers to check both the manufacturing and the expiration dates on the products they buy.

"We need to pay attention to where we by these products from," she said.